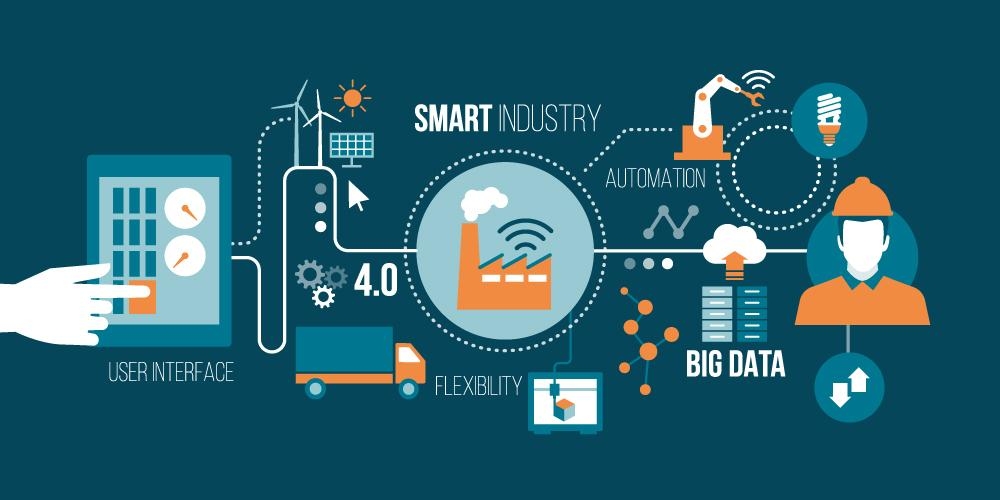

AI-powered supply chain inventory management refers to the use of artificial intelligence (AI) and machine learning (ML) algorithms to optimize the AI supply chain management processes related to Inventory Optimization. This technology helps businesses to automate tasks, gain real-time visibility into inventory levels, and make data-driven decisions.

Traditionally, inventory management has been a manual and time-consuming process, involving the use of spreadsheets and other tools to track inventory levels. However, with the advent of AI and ML, businesses can now streamline their Inventory Optimization processes, reduce costs, improve efficiency, and enhance customer satisfaction.

In today’s fast-paced business world, AI Supply Chain Management (SCM) has become a critical aspect of every organization. Managing inventory is a critical aspect of SCM, and any inefficiencies in inventory management can negatively impact a business’s performance. For instance, overstocking can result in increased carrying costs and reduced profits, while stock outs can lead to lost sales, lower customer satisfaction, and reduced revenue. As a result, businesses must focus on optimizing Inventory Optimization in their supply chain processes.

AI-powered order processing Inventory Optimization offers several benefits that can help businesses to optimize their Inventory Optimization processes.

One of the key benefits is increased efficiency. With the help of AI and ML algorithms, businesses can automate inventory management tasks, reducing the need for manual labor and freeing up valuable time for their team to focus on more strategic tasks. This automation helps to improve the efficiency of Inventory Optimization processes, resulting in increased productivity and reduced costs.

Why AI-powered Supply Network Inventory Management is the Future of Business

Focusing on AI-powered Supply Chain Inventory Optimization is essential for businesses to gain a competitive advantage in the current marketplace. With the increasing complexity of supply chains, businesses are struggling to keep pace with the demand for faster, more accurate, and more cost-effective Inventory Optimization processes. As a result, they are turning to AI-powered solutions to streamline their Inventory Optimization processes, reduce costs, and improve their overall supply chain efficiency.

One of the primary reasons why businesses should focus on AI-powered order processing Inventory Control is because of the efficiency gains it offers. By automating Inventory Control tasks, businesses can reduce the amount of manual labor required and free up valuable time for their team to focus on more strategic tasks. This increased efficiency leads to faster turnaround times, improved productivity, and reduced costs, resulting in a competitive advantage for the business.

Another reason why businesses should focus on AI-powered order processing Inventory Control is because of the increased accuracy of demand forecasting. With the help of AI and ML algorithms, businesses can analyze historical data, identify patterns, and make more accurate predictions about future demand. This, in turn, helps businesses to optimize their inventory levels, reduce the risk of overstocking or stock outs, and ensure that the right products are available at the right time. This leads to improved customer satisfaction and higher customer loyalty, which is essential in today’s highly competitive marketplace.

Benefits of AI-powered Supply Chain Inventory Management

Increased Efficiency

AI-powered Inventory Planning can significantly improve the efficiency of your supply chain processes. With the help of machine learning algorithms, businesses can automate their Inventory Planning tasks such as stock monitoring, order processing, and replenishment. This automation reduces the need for manual labor and frees up valuable time for your team to focus on more strategic tasks.

Improved Forecasting Accuracy

One of the most significant benefits of AI supply chain management Planning is improved forecasting accuracy. With the help of machine learning algorithms, businesses can analyze historical data, identify patterns, and make more accurate predictions about future demand. This, in turn, helps businesses to optimize their inventory levels and reduce the risk of stock outs or overstocking.

Real-Time Tracking

Another benefit of AI supply chain management Planning is real-time tracking. With the help of RFID tags and other tracking technologies, businesses can monitor their inventory levels in real-time. This real-time tracking helps businesses to identify potential supply chain disruptions and take proactive measures to mitigate them.

Cost Reduction

AI-powered Inventory Planning can also help businesses to reduce their costs. By optimizing inventory levels, businesses can reduce their carrying costs, minimize the risk of stock outs , and avoid overstocking. This, in turn, helps businesses to reduce their overall supply chain costs.

Improved Customer Satisfaction

With the help of AI supply chain management management, businesses can improve their customer satisfaction levels. By ensuring that the right products are available at the right time, businesses can minimize the risk of stock outs and improve their delivery times. This, in turn, leads to higher customer satisfaction levels and improved customer loyalty.

Enhanced Data Analytics

AI-powered Inventory Planning can also help businesses to enhance their data analytics capabilities. With the help of machine learning algorithms, businesses can analyze large amounts of data and gain valuable insights into their supply chain processes. This, in turn, helps businesses to make data-driven decisions and improve their overall supply chain performance.

Increased Productivity

By automating Inventory Planning tasks, businesses can significantly increase their productivity levels. This automation reduces the need for manual labor and frees up valuable time for your team to focus on more strategic tasks. This, in turn, helps businesses to achieve greater productivity levels and improve their overall supply chain performance.

Improved Supply Chain Visibility

AI-powered Inventory Planning can also help businesses to improve their supply chain visibility. With the help of real-time tracking and data analytics, businesses can gain a better understanding of their supply chain processes. This, in turn, helps businesses to identify potential bottlenecks and inefficiencies and take proactive measures to address them.

Increased Agility

With the help of AI supply chain management Planning, businesses can become more agile. By automating inventory management tasks, businesses can respond quickly to changing market conditions and customer demand. This, in turn, helps businesses to stay competitive and adapt to changing market conditions.

Scalability

Finally, AI-powered Inventory Planning is highly scalable. As your business grows, the demand for Inventory Planning increases. With the help of AI supply chain management Planning, businesses can scale their Inventory Planning processes to meet the growing demand. This, in turn, helps businesses to achieve greater efficiency and improve their overall supply chain performance.

In conclusion, focusing on AI Supply Chain Inventory Management is crucial for businesses to gain a competitive advantage in the current marketplace. By leveraging AI and ML technologies to optimize Inventory Planning, businesses can achieve greater efficiency, reduce costs, improve customer satisfaction, and enhance data analytics capabilities. Therefore, businesses must focus on optimizing their Inventory Planning processes with the help of AI-powered Supply Chain Inventory Planning to achieve success in the long run.